Calypso offers a variety of sheet metal functions and yet these options are rarely shown in an OEM training class. These measurement techniques may also be used outside of sheet metal applications to better define a measurement strategy.

Circle

Let's say that your part flexes like sheet metal does, this makes it difficult controlling the probe depth when measuring the diameter. Three points around a diameter will help in controlling a consistent probing depth. Calypso will actually use the nominal of the feature to define where these three points should be measured.

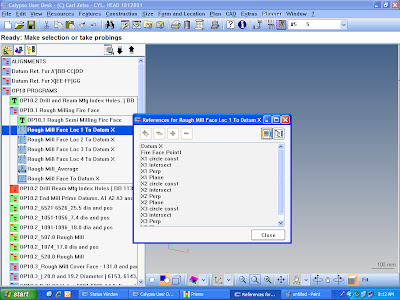

In the circle dialog box click the Projection button, currently it show None

Now select the Working Plane Tab

Define as desired. Set the D2 radius value, as you can see the value is from the nominal edge of the diameter out onto the part. The D1 is the depth the probe will measure the feature.

Because this is a relative measurement function the depth will be consistant no matter where the flexing moves the feature. We will cover more sheet metal applications in future articles.